PRODUCT CENTER

带式输送机

PRODUCT CENTER

裙边

带式输送机

/www/wwwroot/demo26.inquirysystem.net/wp-content/themes/transtack/single-products.php on line 337

"}}" data-widget_type="video.default">

"}}" data-widget_type="video.default">

/www/wwwroot/demo26.inquirysystem.net/wp-content/themes/transtack/single-products.php on line 340

"}}" data-e-action-hash="#elementor-action%3Aaction%3Dlightbox%26settings%3DeyJ0eXBlIjoidmlkZW8iLCJ2aWRlb1R5cGUiOiJob3N0ZWQiLCJ1cmwiOiJodHRwczpcL1wvd2wuZ3htZXNkYS5jblwvdXBsb2Fkc1wvdmlkZW9cLzIwMjMwNzEzXC82ZDUzYTVhOTIxNjQ2MmE4OWNhMzU1M2MwOTEzNzNjOC5tcDQiLCJhdXRvcGxheSI6IiIsIm1vZGFsT3B0aW9ucyI6eyJpZCI6ImVsZW1lbnRvci1saWdodGJveC0zNDQ2MDBhIiwiZW50cmFuY2VBbmltYXRpb24iOiIiLCJlbnRyYW5jZUFuaW1hdGlvbl90YWJsZXQiOiIiLCJlbnRyYW5jZUFuaW1hdGlvbl9tb2JpbGUiOiIiLCJ2aWRlb0FzcGVjdFJhdGlvIjoiMTY5In0sInZpZGVvUGFyYW1zIjp7ImNvbnRyb2xzIjoiIiwicHJlbG9hZCI6Im1ldGFkYXRhIiwiY29udHJvbHNMaXN0Ijoibm9kb3dubG9hZCIsInBvc3RlciI6Imh0dHBzOlwvXC9neG1lc2RhLmNuXC93cC1jb250ZW50XC91cGxvYWRzXC8yMDI1XC8wNlwvMjAwVlMtXHU1YzY1XHU1ZTI2XHU3OWZiXHU1MmE4XHU3YWNiXHU4Zjc0XHU1ZjBmXHU3ODM0XHU3ODhlXHU3YWQ5LXNjYWxlZC5wbmcifX0%3D">

"}}" data-e-action-hash="#elementor-action%3Aaction%3Dlightbox%26settings%3DeyJ0eXBlIjoidmlkZW8iLCJ2aWRlb1R5cGUiOiJob3N0ZWQiLCJ1cmwiOiJodHRwczpcL1wvd2wuZ3htZXNkYS5jblwvdXBsb2Fkc1wvdmlkZW9cLzIwMjMwNzEzXC82ZDUzYTVhOTIxNjQ2MmE4OWNhMzU1M2MwOTEzNzNjOC5tcDQiLCJhdXRvcGxheSI6IiIsIm1vZGFsT3B0aW9ucyI6eyJpZCI6ImVsZW1lbnRvci1saWdodGJveC0zNDQ2MDBhIiwiZW50cmFuY2VBbmltYXRpb24iOiIiLCJlbnRyYW5jZUFuaW1hdGlvbl90YWJsZXQiOiIiLCJlbnRyYW5jZUFuaW1hdGlvbl9tb2JpbGUiOiIiLCJ2aWRlb0FzcGVjdFJhdGlvIjoiMTY5In0sInZpZGVvUGFyYW1zIjp7ImNvbnRyb2xzIjoiIiwicHJlbG9hZCI6Im1ldGFkYXRhIiwiY29udHJvbHNMaXN0Ijoibm9kb3dubG9hZCIsInBvc3RlciI6Imh0dHBzOlwvXC9neG1lc2RhLmNuXC93cC1jb250ZW50XC91cGxvYWRzXC8yMDI1XC8wNlwvMjAwVlMtXHU1YzY1XHU1ZTI2XHU3OWZiXHU1MmE4XHU3YWNiXHU4Zjc0XHU1ZjBmXHU3ODM0XHU3ODhlXHU3YWQ5LXNjYWxlZC5wbmcifX0%3D">

描述

Description

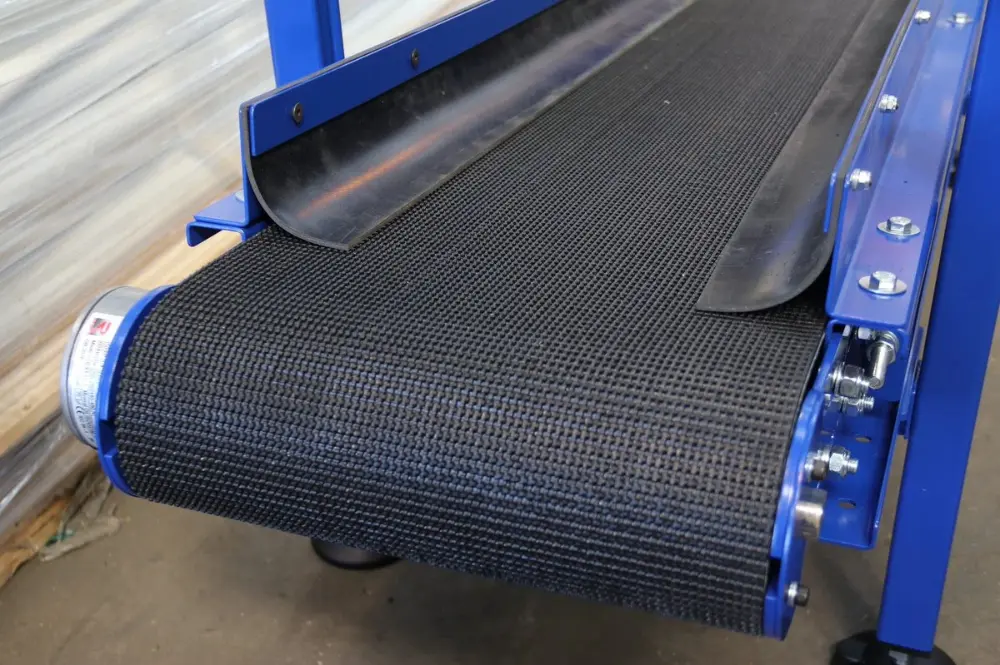

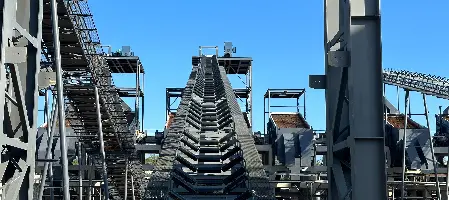

裙边带式输送机指在普通平型输送带两侧,固定有连续、笔直或微弯的橡胶挡边(即“裙边”),以防止物料在输送过程中向两侧洒落的输送设备。

工作原理

Working Principle

裙边带式输送机依靠驱动滚筒与输送带之间的摩擦力,带动输送带及其上物料连续运动。两侧加装的固定式橡胶挡边,将物料限制在输送带宽度范围内,有效解决了因输送带跑偏、抖动或物料堆积角过小而导致的侧向洒落问题。

核心优势

Core Advantages

有效防洒落:从根本上解决粉状、颗粒状及小块状物料在输送过程中的侧向泄漏问题。

结构相对简单:在通用带式输送机基础上对输送带和托辊组进行改进。

成本较低:相比大倾角波状挡边输送机,其输送带和整机成本要低得多。

可密封:可在裙边之上加盖密封罩,实现全密闭输送。

技术参数

TECHNICAL DATA

典型规格表 (以倾角30°、填充率70%为例)

| 规格 (带宽Bx裙边高H) | 带速(v) | 输送能力范围(Q) | 驱动功率范围(长度30m水平) | 典型应用场景 (堆积密度0.8t/m³) |

|---|---|---|---|---|

| B500xH80 | 1.0-1.6m/s | 25-65m³/h(20-50t/h) | 2.2-4kW | 轻质塑料颗粒、种子、小规模配料输送 |

| B650xH100 | 1.25-2.0m/s | 55-130m³/h(45-105t/h) | 3-5.5kW | 粮食、饲料、化工粉末、小型生产线转运 |

| B800xH120 | 1.6-2.5m/s | 100-240m³/h(80-190t/h) | 5.5-11kW | 主生产线、中颗粒输送 |

| B1000xH150 | 1.6-2.5m/s | 150-360m³/h(120-290t/h) | 7.5-18.5kW | 进出仓、煤炭、标准散货码头转载 |

| B1200xH180 | 1.6-2.8m/s | 220-550m³/h(175-440t/h) | 15-37kW | 大型电厂、矿山、港口、建材原料输送 |

| B1400xH200 | 1.8-3.15m/s | 300-750m³/h(240-600t/h) | 22-75kW或更高 | 大型枢纽港、钢铁厂、特大产能加工厂 |